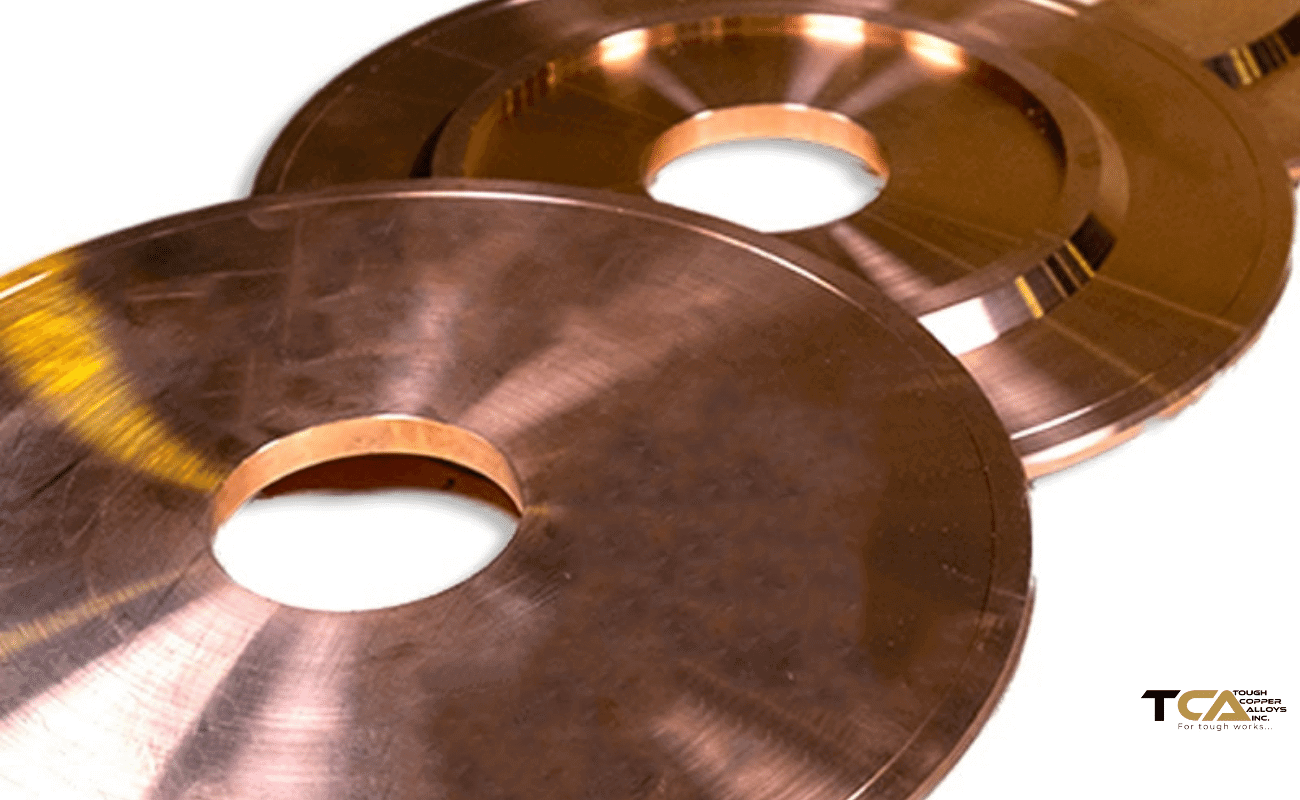

Cupro NS CuNi2SiCr Nickel Silicon Copper Alloy

CuproNSS® is a copper alloy developed by Sağlam Metal.

Suitable for applications requiring high mechanical properties along with good electrical and thermal conductivity.

Automotive Electrical

Clips Clips

Connectors Connectors

Relays Leadframes

Sockets Pins

Springs Relays

Terminals Sockets

Springs

Terminals