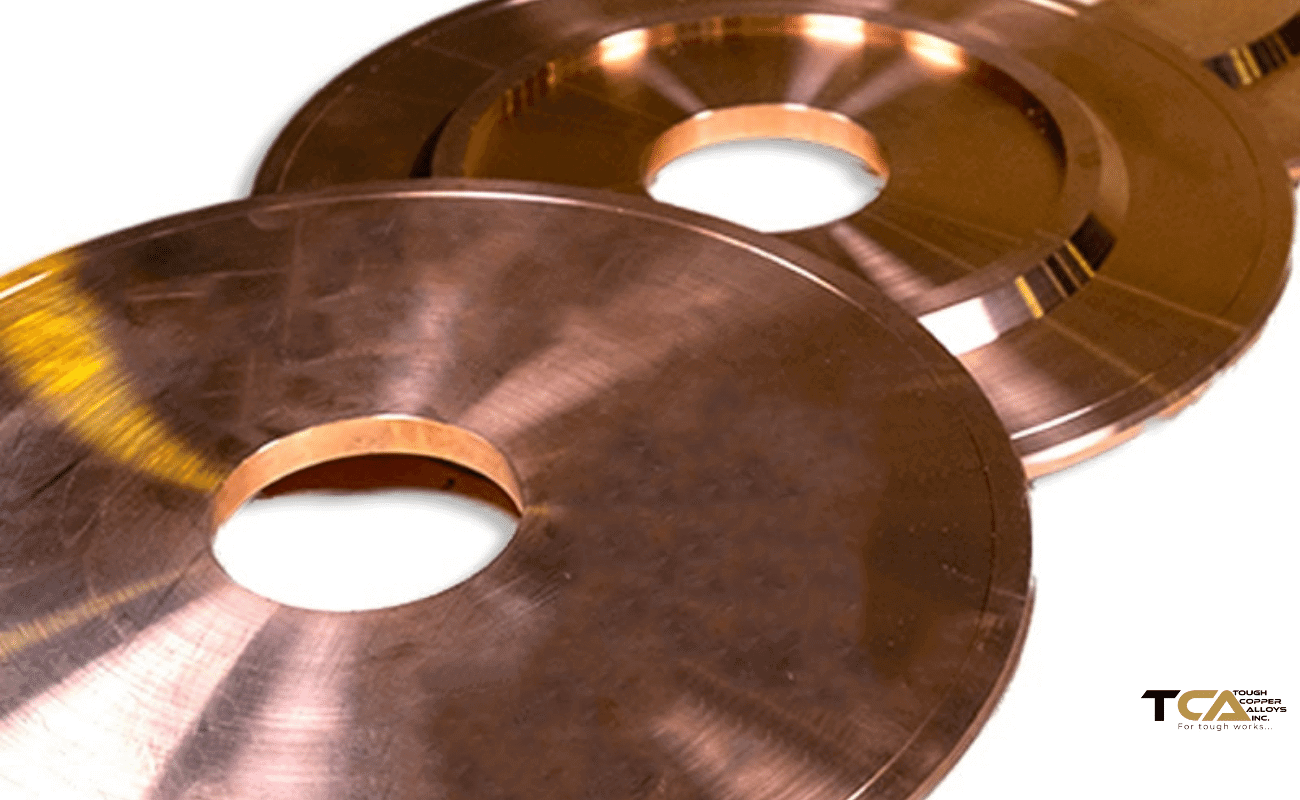

Cupro CNB It is a multi-purpose copper alloy that has both the advantages of the physical properties of copper and moderate mechanical properties.

Cupro NB has higher electrical and thermal conductivity altough the areas of use are the same as Cupro CNB

Electrical Fasteners Industrial

Conductors Fasteners Die casting plunger tips

Connectors, Heavy Duty High Flux Electromagnets

Fuse Clips Springs

Instrument Parts Thermal Transfer Plates

Relay Parts Welding Equipment

Switch Parts