An American duplex aluminium bronze with the addition of iron for added strength and to inhibit grain growth during hot working. C62300 is non-sparking and retains properties down to cryogenic temperatures. C62300 is a balanced alloy, which exhibits a combination of good corrosion, plus oxidation resistance and it also retains mechanical strength and physical properties at moderately elevated temperatures.

Fasteners Industrial Marine

Bolts Bearing Races Marine Hardware

Nuts Bearings

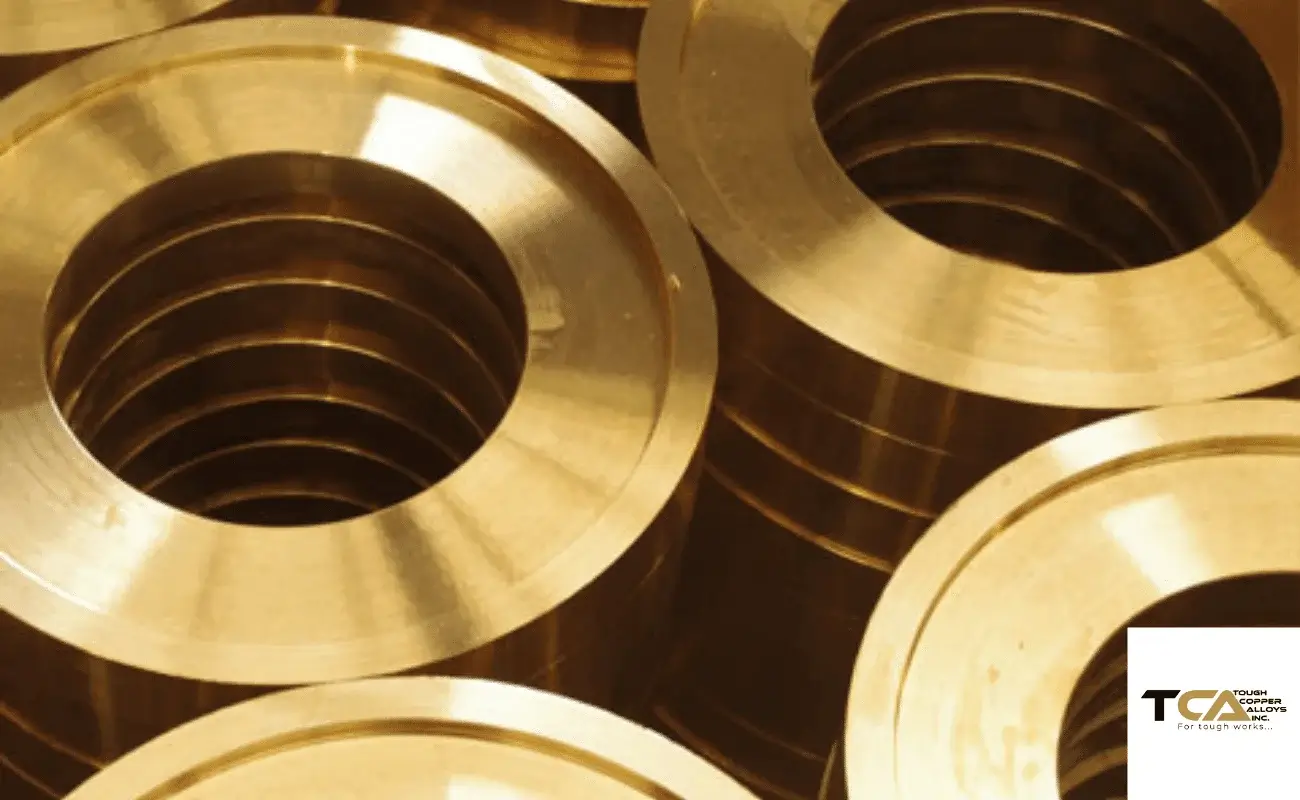

Bushings

Cams

Gears

Pump Rods

Valve Guides

Valve Seats

Valve Stems

Worm Gears