This is a copper alloy with high electrical conductivity.

When alloyed with chromium and zirconium, wear resistance increases.

Wires can be shaped by erosion.

| Consumer | Electrical | Industrial |

|---|---|---|

| Pencil-type & Light Soldering Guns: Tips, Rod Extensions | Resistance welding electrodes | Welding Electrodes |

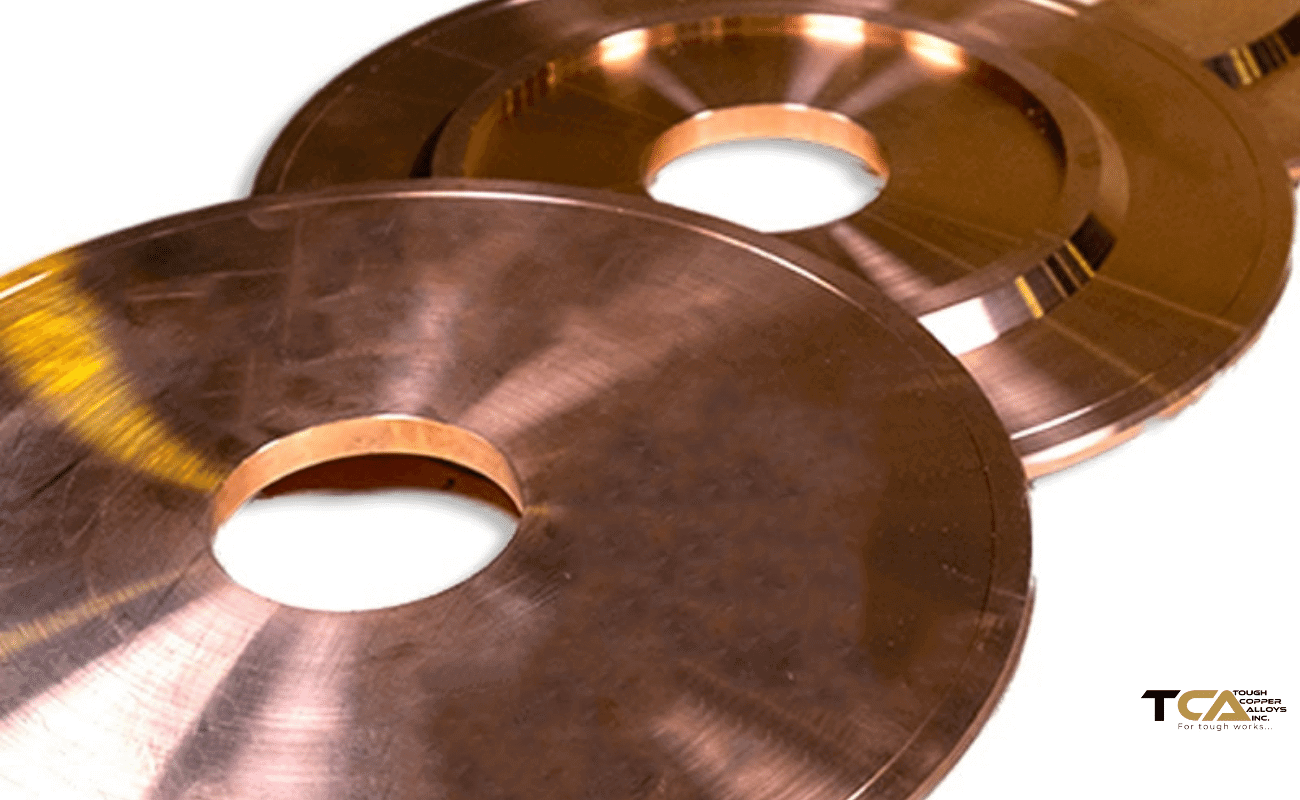

| Welding Wheels, Tips and Rod Extensions |