Leaded high strength yellow brass – copper casting alloy UNS C86400 is a cast brass alloy of manganese bronze and leaded manganese bronze. The chocolate color of UNS C86400 can be attributed to the manganese present in the alloy. The leaded brass is commonly called as architectural bronze. The lead in the alloy enhances the longevity of the alloy and gives it an attractive golden lustre.

Builders Hardware Consumer Electrical Fasteners Industrial Marine Plumbing

Door hardware for Prison Musical Instruments Electrical Components Screw Down Nuts Bearing Cage Blanks Boat Parts Fixtures

Window Hardware Piano Keys Electrical Equipment Bearings Covers for Marine Hardware

Switches Brackets Marine Fittings

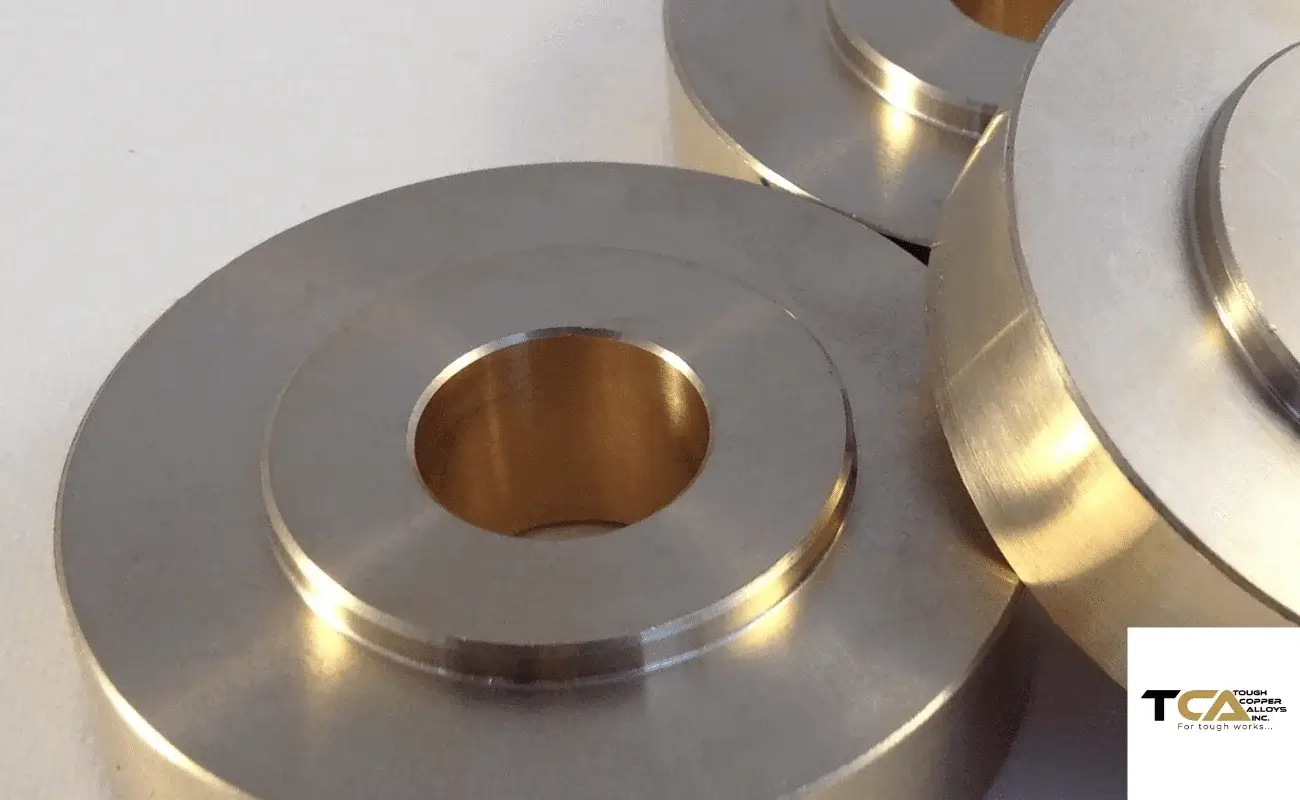

Bushings Marine Hardware

Cams

Fittings

Lever Arms

Light Duty Gears

Machinery Parts

Propellers

Pump Fixtures

Roller Bearings

Valve Stems